With no dissolved oxygen or CO2, no bacteria, and a very high electrical resistivity, ultrapure water is the perfect fluid to inhibit corrosion inside ballast tanks.

In addition to being nature friendly, the use of ultrapure water brings multiple benefits in the design, construction, installation, and operation of floating wind turbines.

Simplification and cost savings

The use of ultrapure water simplifies design and fabrication:

Significant savings in the procurement and fabrication of floating wind turbines and a shorter delivery schedule.

The savings in the design and fabrication should more than offset the cost of ultrapure water.

Flexibility

Ballasting of floating wind turbines from launching of the platform to the final installed configuration with the required draft and anchors tension generally requires several steps.

Structures are quite high and the draft in harbour will limit the ballasting to a fraction of the final or towing ballast. Draft must be sufficient to provide stability for the safe installation of the mast and turbine.

Towing draft may be deeper than the final installation draft on site, to ensure stability during the tow or to facilitate the connection of anchor lines or tendons. In this case, the use of ultrapure water makes de-ballasting of floating wind turbines very easy. Ultrapure water may simply be pumped out or dumped into the sea without any harm to the environment and draft can be adjusted in a very simple way.

y.

Tensioning of anchor lines

Dumping of ballast seawater at the offshore site is banned when the ballast tanks are fitted with sacrificial anodes or when the seawater has been chemically treated.

This may lead designers to implement tensioning systems to achieve the required anchor lines tension. Such systems are not required anymore or may be simplified when ballasting is done with ultrapure water, since de-ballasting becomes a safe and easy operation.

.

Active ballast systems

Some floating turbine concepts include an active ballast. Needless to say that a close circuit active ballast with ultrapure water will not be affected by internal corrosion or deposits, thus increasing its life and reliability.

Ballast integrity monitoring

The control and monitoring of ultrapure water quality inside the ballast is very easy. Resistivity and pH readings (which are corelated) are sufficient to characterize the purity of the water. Thus, a permanent monitoring of the ballast can be done by telemetry.

A camera or optical fibre may even be inserted in the ballast for close inspection since ultrapure water remains fully transparent.

In case of a breach in the ballast due to a structural failure, a collision with a ship or floating object or external corrosion, which may not be immediately noticed, the ingress of seawater will be immediately detected by a significant change in the resistivity of the ballast water.

Adaptable to other concepts of floating wind turbines

Ultrapure water can of course be used to ballast SPAR buoy floating wind turbines.

In the case of TLP designs, a fixed ballast tank or a temporary one is fitted to the structure for the purpose of de-ballasting and anchor leg tensioning. The use of ultrapure water rather than seawater will greatly simplify ballasting and de-ballasting operations.

FUTURE APPLICATIONS

Ultrapure water clearly brings a novel approach to resolve the issues around the ballasting of floating wind turbines.

It will be beneficial also to other components of the floating wind industry.

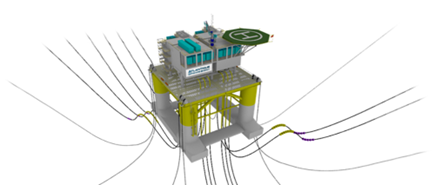

Offshore substations

The electrical substations associated with commercial large scale wind farms will be massive structures. Ballast volumes are likely to be in the range of 50,000 m3 for those platforms. Use of ultrapure water will greatly enhance the design optimization as well as the operation and maintenance of such facilities.