THE RIGHT WAY TO BALLASTING FLOATING WIND TURBINES: ultrapure water

A solution which will make floating wind power a true clean renewable energy, eliminating the need for coating, sacrificial anodes and harmful chemicals inside the ballast tanks.

PRODUCTION AND DELIVERY OF ULTRAPURE WATER

Our goal is to produce and store large volumes of ultrapure water and deliver them when and where it is needed: harbours, fabrication yards and offshore.

Such quantities of ultrapure water, an average of 10,000 tonnes per floating wind turbine of 10 MW, cannot be sourced onshore. They must be produced offshore, from seawater.

Ultrapure water can indeed be made from seawater, what requires a very specific technology, and a proven field experience is a prerequisite to produce ultrapure water at the flowrates and volumes involved in the ballasting of floating wind turbines.

As a matter of fact, this is our background.

BACKGROUND AND EXPERIENCE

Hansen Marine Exploration’s Technical Director is the inventor and developer of the first drinking water bottling ship named ÔDeep One. This ship has been pumping and processing sea water at 50 m3/hr to supply a drinking water bottling plant onboard.

See ÔDeep One – http://odeep.one.free.fr

The main intermediate product of this process, which uses no chemicals, is ultrapure water. The process equipment can easily be scaled up to double the flowrate.

From this field proven experience, coming after years of developing and fine tuning the seawater treatment plant, Hansen Marine Energies has the know-how to produce and deliver pure water from seawater with a reliable process, at flowrates compatible with the floating wind power development requirements.

VALIDATION TRIALS

Lab tests will soon be performed in coordination with a major Energy Producer, an EPCI contractor and a Classification Society to validate our solution.

SPECIALIZED VESSEL FOR FLOATING WIND ENERGY

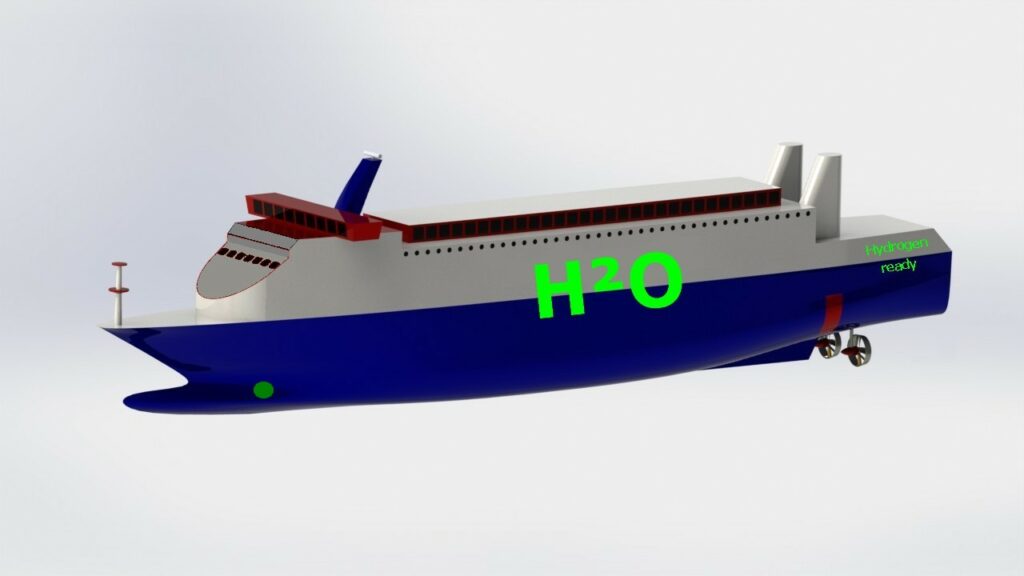

Hansen Marine Energies is designing a water treatment and storage ship specific for this application. This vessel will support the process equipment and supply ultrapure water to the wind floating turbines construction harbours as well as to the offshore sites.

The Factory Ship H2O will have the lowest possible carbon footprint and will meet the highest requirements in terms of environment protection.

CARACTERISTICS OF THE FACTORY VESSEL

Length Overall: 119.9 m

Length between Perpendiculars: 114.00 m

Moulded Breadth: 18.80 m

Depth to Main Deck: 10.50 m

Depth to Poop Deck: 13.6 m

Design Draught: 7.10 m

Deadweight at Summer Draught: 11345 T

Service Speed: 13.5 knots

Service Range: 8500 miles approx

CAPACITY: 10 000 M3 Ultrapure Water H2O

Cargo Tanks: 12

Production : 100 M3/H

Propulsion : 3 x 12DZD BEHYDRO 3x 2,670 kW

Diesel electric 2 pods DP 3

Ballast Water Capacity: 4000 m³

Anti-roll system

The ship is equipped with 30 berths

We look forward to implementing this innovative technology which will set a new standard not only for floating wind turbines but also for other floating units in the offshore energy industry.