The use of ultrapure water eliminates the risks associated with works such as scaffolding, blasting, coating or painting, possibly welding of anodes, in the confined space of ballast tanks and their associated hazards.

There is no need either to handle chemical products to treat the ballast water, avoiding hazards to the health and safety of the workers involved in the ballasting operations.

Equally importantly, ultrapure water eliminates the injection of harmful products such as the biocides, corrosion inhibitors and oxygen scavenger in the ballast water and thus the risks generated by spillage of treated water into the sea.

The same applies to dissolved sacrificial anodes which render the ballast water inappropriate for dumping into the sea and requires its disposal and treatment in case de-ballasting is needed.

On the other hand, ultrapure water may be dumped into the sea without any damage to the marine fauna or flora. It is like rainwater falling on the sea. Accordingly, even in case of an accident, or technical de-ballasting, ultrapure water will cause no harm to the environment.

IMO Ballast Water Management Convention D2 new regulation will be enforced in 2024 and will require a Ballast Water Management System for each ship. This regulation is designed to minimize the transport and discharge of viable organisms and harmful microbes, and concerns mostly merchant ships. However, the floating wind turbines ballasted with seawater at quayside are transported offshore and could be subject to this IMO regulation in case of de-ballasting.

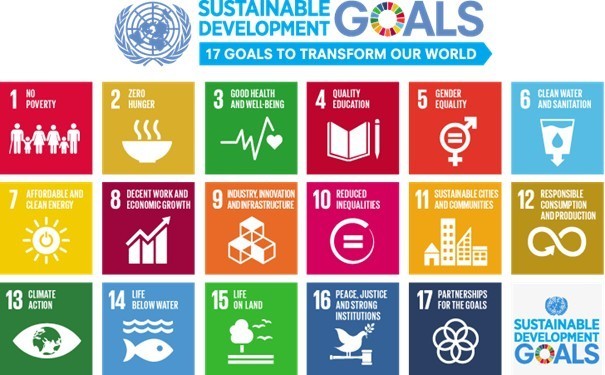

HANSEN MARINE ENERGIES fully SUPPORTS the UN Sustainable Development Goals

The United Nations have established 17 Sustainable Development Goals (SDGs) to end poverty, protect the planet, and ensure peace and prosperity for all. Implementing an innovative solution for the ballasting of floating wind turbines using ultrapure water will contribute directly to several SDGs.

Overall, the implementation of an innovative solution for ballasting floating wind turbines using ultrapure water will have a positive impact on several of the key UN’s Sustainable Development Goals.